Mark One Composite 3D Printer Review14 July 2015 | Sabina Gonzalez-George  The new Mark One Composite 3D Printer: Our Review

In June, we held the official UK launch (read more about the launch) of the new Mark One Composite 3D Printer by MarkForged, a printer that has been exceptionally well received. As we have been putting ours through its paces, we wanted to give you the inside scoop on this new 3D printer. Read on for our thoughts.

So, why is the Mark One so revolutionary?

In short, the Mark One 3D printer is unique. It presents completely different capabilities from other desktop 3D printers currently on the market...

Further insights into using and printing with the Mark One 3D printer

Firstly the build quality of the machine itself needs to be mentioned. The printer is obviously well thought out - it was developed by a MIT aerospace engineer who wanted to use 3D printing hardware to produce high-strength parts with an end-use. The feel and structure of the Mark One, as well as the components used have a very high quality feel about them. Plus, on a complete side note it looks fantastic!

One of the aspects that our 3D printer experts really enjoy is the fact you can control the Mark One 3D printer over Wi-Fi, further enhanced by the fact the Eiger software is online. This idea was developed from scratch, so you get an excellent user experience. The workflow is very smooth and for those businesses with high intellectual property considerations (and worried about having the software online), Eiger takes security very seriously, something well guarded by the MarkForged Team.

The Eiger software itself needs a further mention as it really is an intelligent 3D printing tool. The recent upgrade (see our previous Eiger update article) means that the software is now even more intuitive and gives a huge amount of flexibility as you can change your settings on a layer-by-layer or grouped-layer basis, giving you a very high level of control of your final build.

Finally, the attention to detail on the Mark One is very good. For example, MarkForged have thought about the fact that Nylon is prone to taking on moisture, so there is an adapted dry-box supplied with the printer for storing the material, with a direct feed into the printer. It is also worth highlighting that using Nylon as the base material, offers not only high-strength qualities to the end part, but also flexible properties.

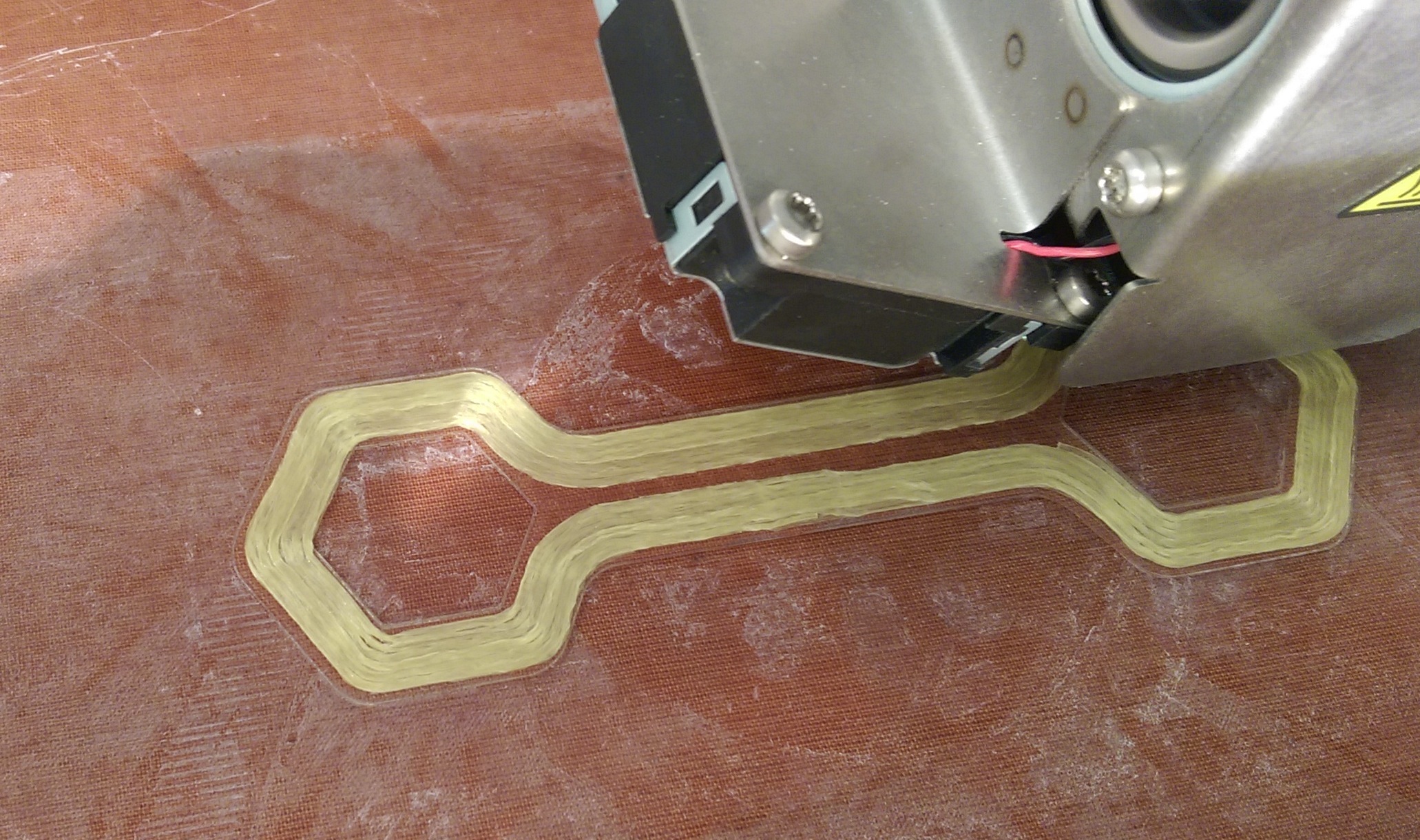

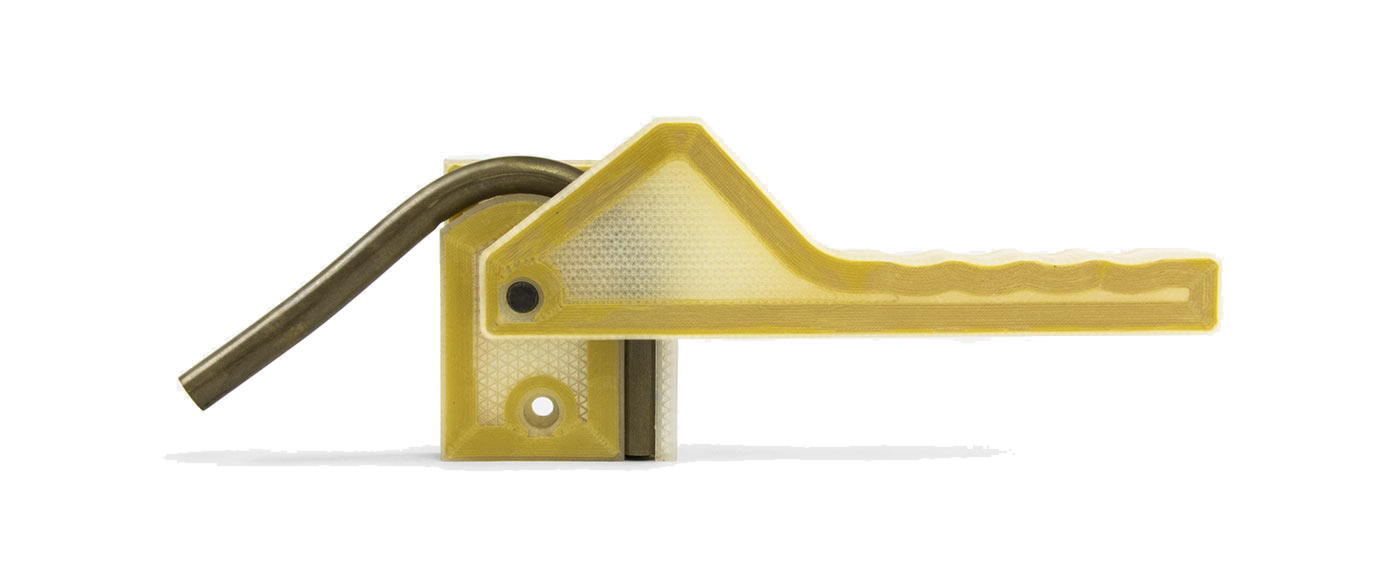

Overall, the unique Mark One Composite 3D Printer has excellent qualities that are particularly well suited for tooling, moulds, end-use parts (such as custom designed car components) and functional prototyping applications. The use of Nylon with the option to add reinforced fibres in Carbon Fibre, Kevlar and Fibreglass and embed components such as electronics and sensors during the print process presents a unique capability for Businesses at very low cost. The printer capabilities are matched and supported by the intuitive Eiger software allowing for high levels of control over the finished 3D print.

Our summation: An exceptional 3D printer with excellent engineering applications.

Available in two formats: The Mark One Composite Printer and the Mark One Professional Kit. The Professional Kit enables you to add Kevlar reinforced fibres and comes with a whole host of additional consumables and spares.

Contact the CREAT3D Team to discuss the Mark One Composite 3D Printer in more detail, or place your order now for next day delivery.

|

| ||