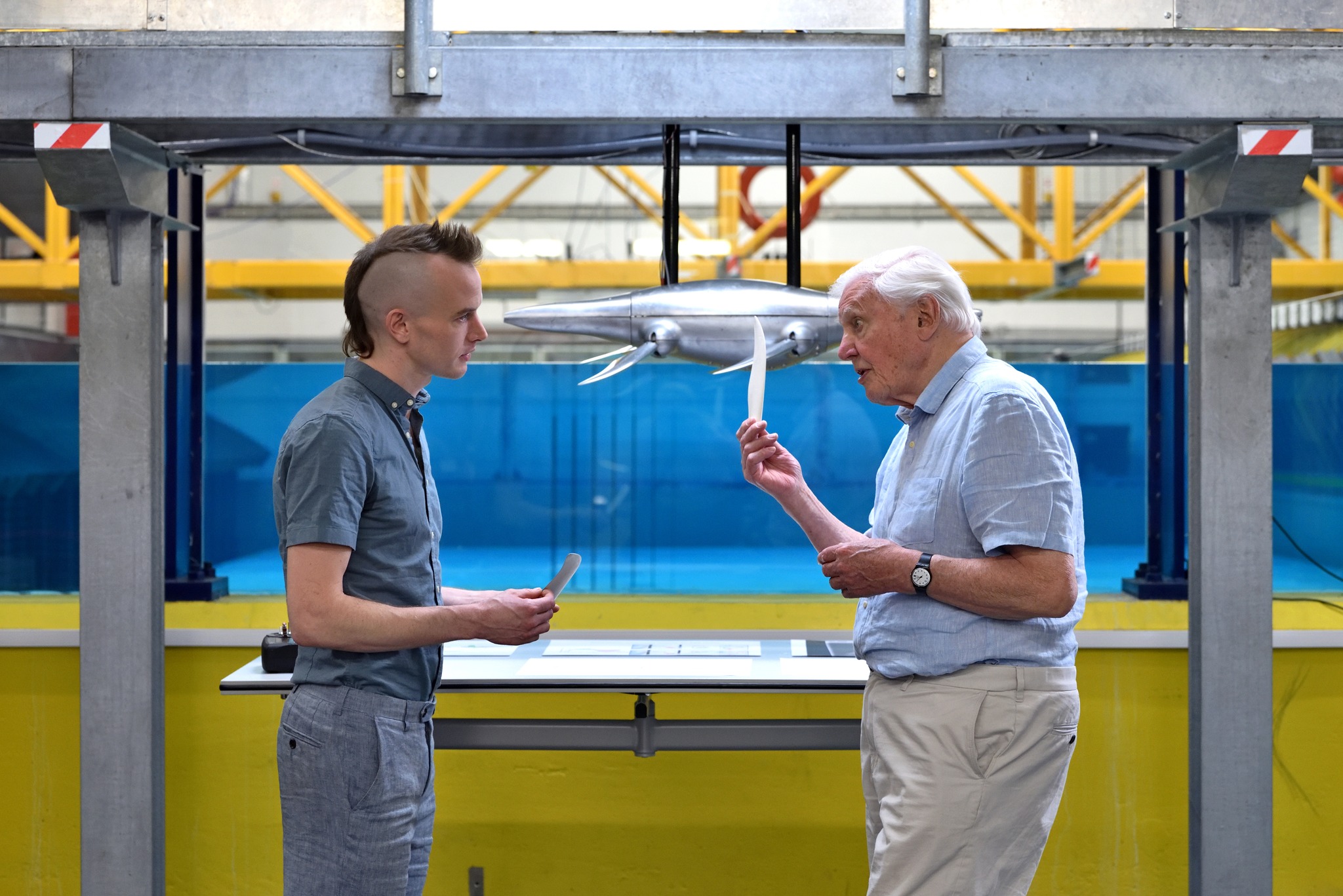

3D Printing Tells the Tale of a Sea Monster15 January 2024 | Sabina Gonzalez-George At CREAT3D we love to see the projects our clients produce with their 3D printers. And this story is a wonderful combination of the power and impact of modern robotics and mother nature. Dr Luke Edward Muscutt, an aerospace engineer working at Imperial College London has embarked on a fascinating robotics project that will take him back millions of years and result in an encounter with Sir David Attenborough. In 2023, there was a discovery of a large fossil on the Jurassic coast in Dorset, UK. Spotted originally by its snout, the fossil's resting place was 12 metres up on the cliff face. Once excavated, the 2m long fossil was found to be the skull of a pliosaur, an ancient marine reptile, known as the Tyrannosaurus Rex of the sea. So how does the fossil discovery relate to Additive Manufacturing? Well as part of the learnings about the pliosaur, Sir David Attenborough engages the latest technologies, including a CT scan of its snout to understand the reptile's biological make-up at the University of Southampton, a 3D model of the pliosaur skull at Bristol University to determine its bite force; and a robotic model developed using 3D printers to show how it would have swam at Imperial College London. Meet Flip, the World's First Scientifically-Accurate Plesiosaur Robot. "I continue my research into the hydrodynamics of plesiosaurs in my spare time. This has recently involved the design and manufacture of a swimming plesiosaur robot, which I have been testing in the hydrodynamics lab at Imperial College London" explains Luke. Luke and his team focussed research and testing on the plesiosaur's flippers, first building a flipper system mounted on a gantry, without a head or tail. Once tested, this then progressed into a fully functioning prototyping.

The robot is 1m long, and the body is split up into 10 sections to enable them to be printed in separate components on the Form 3L. Pushing the 3D printer to it's maximum build space, the parts fitted on the build plate with less than 1mm to spare when printed on the long diagonal. "I have been extremely impressed with how well the parts fitted together, and it has enabled me to utilise novel mechanism designs and assembly procedures, such as split bearing housings and internal bolted flanges" explains Luke.

To learn more;

To adopt Additive Manufacturing in-house, contact our team to discuss the best equipment for your needs. |

| ||||||