From Surface to Seabed: How Additive Manufacturing is Powering a New Generation of Underwater ROVs

Wednesday 12th November 2025

When it comes to robotics, Additive Manufacturing (AM) is already proving its value, from UAVs in the air, to UGVs on land. Now, engineers are taking that same design freedom below the surface, applying 3D printing to the world of underwater ROVs (Remotely Operated Vehicles).

Building for subsea environments isn’t just about waterproofing. Components are subjected to a range of different requirements, from withstanding extreme deep pressures, resisting corrosion from salt water, to performing reliably in conditions where repairs are difficult and access is limited. Traditional manufacturing often struggles to deliver the precision, speed and cost-efficiency needed for these unique challenges, but 3D printing is changing that.

Engineering for the Deep

Designing parts that can operate hundreds of metres underwater requires accuracy, strength and watertight integrity. Traditionally, such components would be machined from metal or injection moulded, often at high cost and long lead times. Minimum order quantities and tooling requirements make one-off or low-volume production uneconomical, a common barrier for robotics developers or research teams.

By contrast, Additive Manufacturing allows these components to be designed, produced and tested in-house, quickly, affordably, and without compromising performance. Engineers can print pressure housings, brackets, mounts and actuators overnight, using high-performance resins or composite materials.

It’s this ability to move from idea to functional part in days, not weeks, that is accelerating innovation across the subsea robotics sector.

Case Study: SoSub - ROVs for Deep Sea Repairs

Southern Ocean Subsea (SoSub), based in Australia, design and manufacture underwater robotics systems for industries such as aquaculture, offshore wind and marine research. Working with Formlabs, they’ve built a fleet of SLA printers that enable rapid development of waterproof, high-precision ROV parts.

The company’s engineers have printed watertight enclosures in Tough 2000 and Rigid 10K Resin, capable of withstanding pressures at depths of over 600 metres, and in some cases, beyond 1000 metres.

“We can make a subsea actuator rated to 600 metres in half a day,” explains SoSub engineer Miles Lewis. “3D printing removes manufacturing as the bottleneck. The bottleneck becomes our imagination.”

Their flagship project, the Squid Lock, highlights the value of 3D printing in rapid, functional design. Created for use in offshore fish farms, the Squid Lock acts like a robotic hand, gripping and manipulating floating fishing nets with precision. Within just six weeks, SoSub went from rough concept to fully functional ROV units, each combining 3D printed teeth and resin housings strong enough to exert over 400 kg of pulling force underwater.

By designing with Additive Manufacturing in mind, SoSub were able to consolidate complex assemblies into single printed components, simplifying production, improving sealing, and reducing the need for multiple machining operations.

Squid Lock enclosure printed in Tough 2000 Resin. Photos courtesy of Formlabs and SoSub

Case Study: ECS Special Projects – Bespoke Subsea Components

Back in the UK, Dorset-based ECS Special Projects specialise in mechanical assemblies for marine, sub-sea and defence applications, from EOD (explosive ordnance disposal) systems to autonomous ROVs.

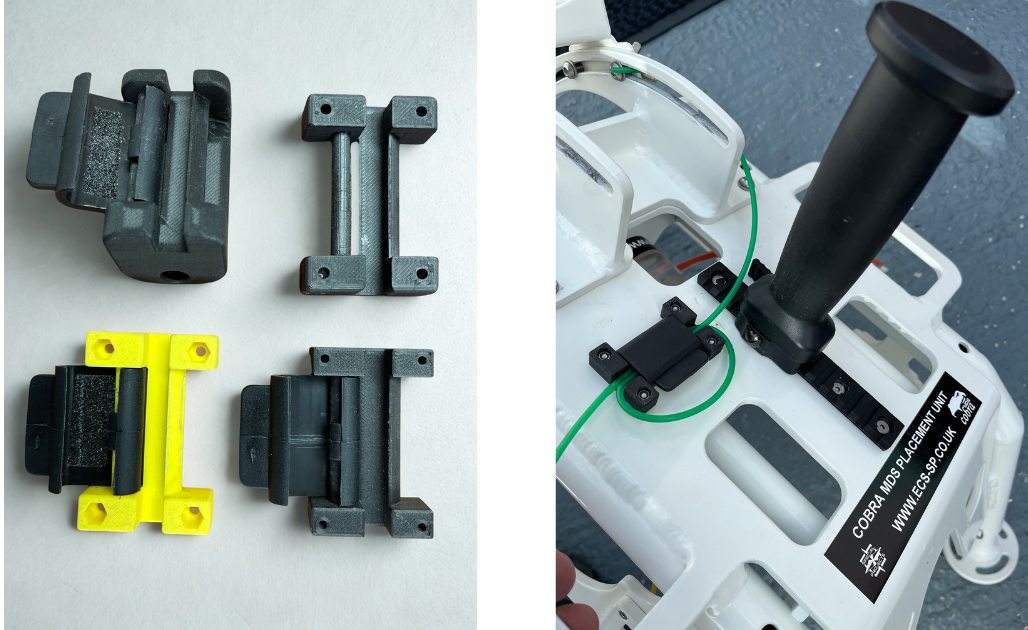

ECS adopted Markforged composite 3D printers to produce custom components, including a shock tube strain relief clip designed to protect wiring during subsea operations.

Previously, the part would have been machined from Nylon, with a minimum order of 200 units at £10 each. Using Markforged AM technologies, ECS now print the same component in Onyx material (Nylon with micro carbon fibres), at a cost of just 40p per part and with a 96% cost saving.

Just as importantly, design improvements are simple and instant. Variants can be printed threaded or non-threaded, with or without drop-in lock nuts, without additional tooling or supplier delays.

“Time is the best outcome of using Additive,” says Steve Randall, Operations Director at ECS. “To manufacture something traditionally takes 2–3 weeks. Now we can design something and have it on our desks the following morning.”

For ECS, 3D printing isn’t just an R&D tool, it’s enabling low-volume, end-use production for external customers, opening new revenue streams while maintaining full design control.

Design for Depth: Lessons from Land, Air and Sea

Across all sectors, from autonomous drones and ground vehicles to underwater ROVs, the same engineering goals apply: make parts lighter, stronger, more efficient, and faster to produce.

Additive Manufacturing makes this possible. Complex geometries, pressure-rated housings, and integrated functionality can be achieved in a single printed component. There’s no tooling, no MOQ, and no waiting on external suppliers.

In our previous blog on 3D Printing for Underwater Applications, we explored how Additive technologies are being used to produce watertight housings, pressure bulbs, and test casings for subsea systems, designs that would be prohibitively difficult using conventional methods. The same principles now apply at production scale, where ROVs must deliver reliability and performance under immense pressure.

Designing for Additive (DfAM) also means flipping the traditional mindset:

- Reducing multi-part assemblies into a single watertight design

- Integrating O-ring seals, threads, or textured surfaces directly into the print

- Combining materials, for example, a rigid printed body with flexible or metal-embedded components, to achieve full functionality without post-assembly

For engineers, this means fewer constraints, faster testing cycles, and the ability to take design risks safely.

Future-Ready Robotics, Made Locally

From the skies to the seabed, 3D printing is giving robotics engineers the flexibility to create, test and refine designs faster than ever before. Whether you’re developing aerial drones, ground-based UGVs, or subsea ROVs, the same AM advantages apply: lower costs, faster iteration, and freedom to innovate without manufacturing bottlenecks.

Additive Manufacturing is redefining what’s possible, even under pressure.

👉 Explore how AM could enhance your ROV or subsea systems. Request a test print or speak to our engineering team to discuss how in-house or on-demand 3D printing could support your next project.