3D Printing Beneath the Waves: Proving AM Parts Underwater

Monday 8th September 2025

Additive Manufacturing (AM) has transformed how engineers design and produce parts on land – from rapid prototypes to production tooling and end-use components. But what happens when the requirements shift from the factory floor to the ocean floor?

For subsea and marine environments, the engineering challenge is extreme: watertight enclosures, components that can withstand crushing pressures, and materials that won’t degrade in saltwater. Traditionally, these parts require expensive machining or moulding, often with long-lead-time supply chains. AM changes this equation.

With the right design, process, and materials, 3D printing enables:

- Watertight enclosures with precise seals and integrated features

- Lightweight, strong structures that distribute pressure effectively

- Rapid, customised production of parts for defence, subsea robotics, and oil & gas operations

The question is: can AM parts really survive – and perform – when fully submerged? We decided to prove it.

Proving Watertight 3D Prints: Our Test

When evaluating AM techniques for watertight parts, SLA stood out as the clear choice. SLA parts are isotropic, with each layer chemically bonded to the next, eliminating porosity. The smooth surface finish also allows for excellent tolerances, making it ideal for watertight enclosures and assemblies.

- FDM parts are porous due to gaps between extruded layers

- SLS parts are not porous, but often require additional sealing

- SLA delivers dense, fully bonded layers with no air gaps

To demonstrate watertight performance, we designed and printed a pressure bulb on the Formlabs Form 4 (SLA) using Rigid 10K Resin selected for its watertight properties, strength under pressure, and proven durability in marine environments.

We submerged the part in a container of water and pumped air into the bulb.

Print Stats:

Pressure Bulb 3D printed on the Formlabs Form 4 resin 3D printer using Rigid 10K resin.

Material Quantity: 30.75 mL

Cost: £8.00

Print Time: 1h 58 mins

Wash Time: 20 mins

Cure Time: 1h 00 mins

The Results

The test part was submerged to a pressure of 87 PSI – equivalent to 61 metres depth.

Outcome:

✅ Pressure: 87 PSI

✅ Depth: 61 metres

✅ Result: No bubbles. No leaks. No failures.

A watertight, reliable component – straight off the printer.

Designing for Strength Under Pressure

The bulb was designed with smooth, continuous curves to distribute pressure evenly and increase structural integrity. Sharp corners or angles create weak spots where cracks and leaks can form under stress.

A single threaded opening was designed to match the air compressor nozzle, enabling an exact fit and secure seal – made possible by the high tolerances achievable with SLA printing.

Why Rigid 10K Resin?

- Has a lower percent weight gain (0.1%) over 24 hours when in immersed in salt water (vs. 0.6–0.8% for other resins)

- Tested to withstand pressures equivalent to almost 4,000m depth, with implosion pressure of 5626 PSI

Why It Matters

Operating underwater leaves no margin for error. Equipment must withstand pressure, corrosion, and continuous exposure to harsh conditions. Traditionally, this means long lead-times, specialist machining, and high costs for bespoke parts.

Additive Manufacturing changes that:

- Fast access to solutions – Engineers can design and produce watertight housings or fittings within hours, rather than waiting weeks for traditional manufacturing

- Low cost

– Our pressure test part cost less than £10 to produce, proving that watertight, high-performance components don’t have to come with a premium price tag

- Customisation on demand

– AM allows parts to be tailored precisely to fit sensors, cabling, or assemblies, reducing leak points and ensuring reliable performance

- Proven watertight

– With the right design and materials, AM delivers fully sealed, pressure-resistant parts that meet the demands of subsea and defence environments

In short: 3D printing delivers the speed and flexibility engineers need, without compromising on watertight integrity.

Real-World Underwater Applications

This isn’t just a lab experiment – it connects directly to industries where reliability under pressure is non-negotiable:

- Defence

– underwater drones and autonomous vehicles need durable housings, fixtures, and cable management

- Marine / Sub-Sea / Oil & Gas

– sensor housings, enclosures, and custom fittings printed on-demand keep operations running offshore

- Explosives & Cabling

– bespoke housings for delicate or high-risk equipment including drones and ROVs can be produced quickly and reliably

Organisations like NOAA and companies such as Southern Ocean Subsea are already harnessing AM for subsea equipment, proving its value in the field.

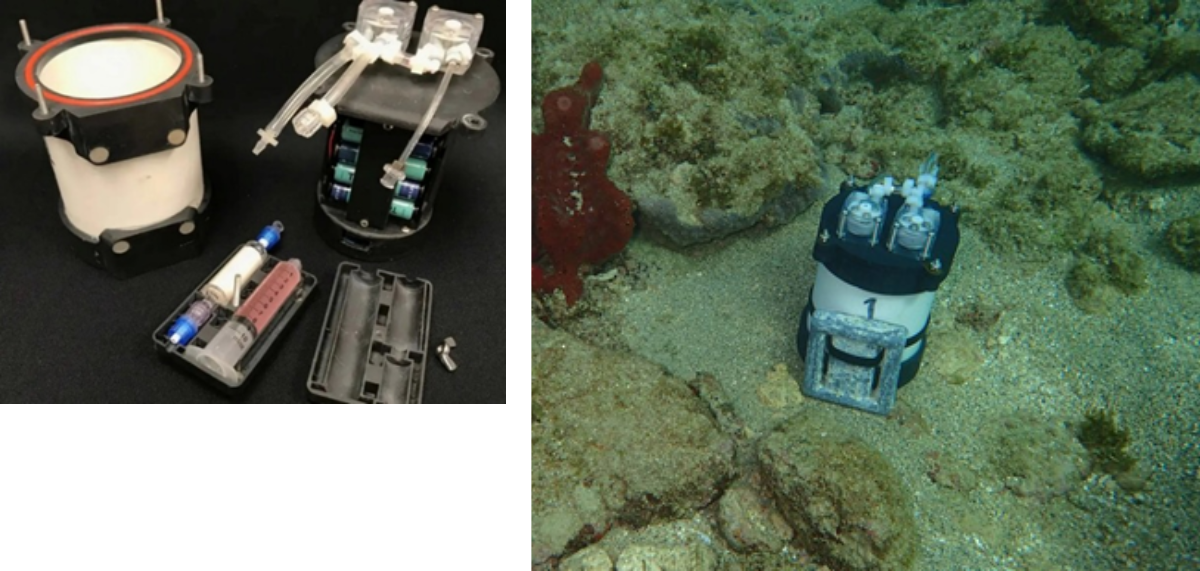

NOAA’s Atlantic Oceanographic and Meteorological Laboratory

NOAA’s Atlantic Oceanographic and Meteorological Laboratory (AOML) develops specialised watertight and pressure resistant scientific equipment to study and protect coral reefs.

Application: Sub-surface automated environmental DNA (eDNA) sampler, waterproof and submersible to 55m

Cost saving with AM: £575

Benefit: Customised components with exact connection points and through-holes to enable sampling

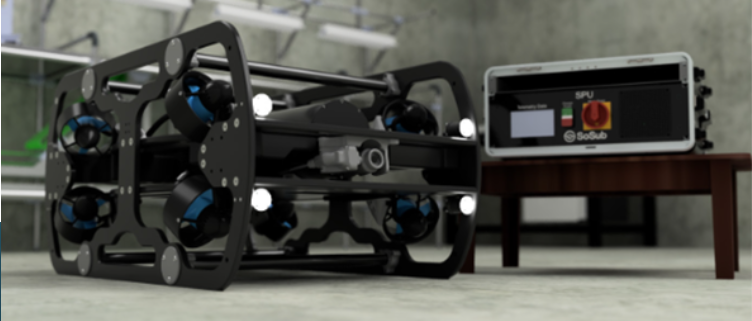

3D Printed Underwater Robotics for Deep Sea Repairs

Southern Ocean Subsea (SoSub) is a manufacturer of underwater robotic systems.

The company uses 3D printing in the development of its remotely operated vehicles (ROVs), producing complex parts for underwater operations.

Rather than adapting traditional parts for production, they design components with AM in mind, creating complex, custom, and waterproof parts that would be difficult or impossible to produce with conventional methods. By consolidating multiple components into single printed pieces, they reduce assembly steps and simplify operations. A pressure enclosure printed in Rigid 10k succeeded beyond 1000m in depth.

Application: APAMA ROV: SoSub’s underwater vehicle designed for inspection, maintenance, repair and cleaning of nets.

Benefits of using AM: The ROV incorporates different 3D printed pressure vessels. Other components are customised to meet specific client requirements such as bespoke brackets or specialised tools.

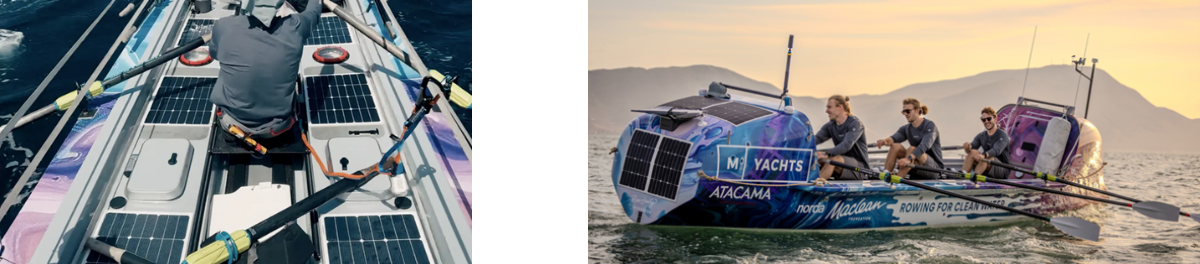

Journey of the Maclean Brothers

The Maclean brothers have claimed a new record for rowing non-stop and unsupported across the Pacific Ocean after almost 140 days at sea, over a 9,000 mile journey across the Pacific Ocean from Peru to Australia.

Their boat, the Rose Emily, was modified with 3D printed components designed to improve safety, efficiency, and comfort during several months at sea.

Ewan Maclean, an engineer with experience in 3D printing, created approximately 40 to 50 custom parts using a Form 4 printer and various Formlabs resins. Tough 2000 was used for parts that go on the exterior of the boat and are most exposed to the elements, as it is a sturdy and robust material. Clear V5 was used to make custom moulds for silicone parts.

Parts needed to fit specific shapes on the boat or the crew, tolerate continuous exposure to marine conditions, and produced quickly before departure.

- Starlink mount: Designed to fit the curvature of the boat, installed at a very specific position to guarantee reception and avoid water build-up

- Jetboil gimbal: Enabled them to keep the Jetboil level whilst boiling water on the boat

- Removable bed: 3D Printed connectors used to install a bed at the back of the boat

- Ergonomic seats: Custom ergonomic seat moulds designed to produce silicone cushions

Read the full story

Designing for Watertightness

One key element is determining the requirements for your watertight part; Does the part need to be splash-proof or fully submerged? What is the type of water exposure – for example is it salt water, river or mangrove? If the part is being submerged, to what depth? What pressures will it need to resist? All these factors will affect both the design of the part and the material used.

When designing for environments with prolonged UV or saltwater exposure, parts may need high impact resistance and durability. Tough resins like Tough 2000 or Durable have been proven in demanding applications, such as the Maclean Brothers cross-Atlantic rowing boat.

For above-water or splash-proof parts, standard resins could be a good option whilst still being watertight.

Sharp corners and sudden changes in geometry should be avoided, as they make sealing difficult and create stress points in the part. Instead, rounded edges, stable geometries, and adequate wall thickness (over 1.5mm for SLA, 2mm for SLS) improve strength and prevent leaks.

Precision features such as threads, interlocking joints, and mating surfaces reduce the need for extra fasteners, limiting potential leak paths. Where joints are needed, O-rings or gaskets can be used to improve the seal. The grooves need to be designed to ensure a tight fit but without over-compression.

Additive Manufacturing allows for custom watertight enclosures that fit internal components precisely, minimise openings, and incorporate all necessary features into a single, tailored design.

Download the white paper

Post-Processing for Extra Protection

SLA produces inherently watertight parts and SLS can achieve watertightness through careful design, FDM prints often require additional sealing to prevent leaks.

There are a number of post-processing methods that can be used to improve part watertightness further:

- Epoxy Resin coatings: Epoxy resins form a durable, continuous barrier that penetrates and seals surface porosity on FDM parts in particular. With proper surface preparation (cleaning, sanding) and multiple thin coats, epoxy offers strong water resistance.

- Silicone coatings: Flexible and chemically resistant, silicone sealants are ideal for parts exposed to temperature cycling, movement, or harsh environments. They can be sprayed, brushed, or dip-applied to create a uniform waterproof layer, and are especially useful where flexibility is required over rigidity.

- Solvent Smoothing: Using chemicals to smooth (partially dissolve) the outer surface layers of a part so it bonds layers and eliminates micro-gaps. This produces a smoother finish while sealing pathways for water ingress, though it requires careful control to maintain dimensions.

- Temperature treatment: Heat guns can fuse an FDM part’s outer layers to close surface gaps. Annealing in an oven bonds layers throughout the part for greater strength, temperature resistance, and reduced porosity.

Below the Surface, Above Expectations

Our test proves what’s possible: with the right design and material, 3D printed parts don’t just survive underwater – they thrive.

Whether it’s keeping underwater ROVs and drones mission-ready or operational, protecting subsea cabling, or producing housings that withstand crushing depths, AM is helping engineers solve problems, fast and cost-effectively.

If you’re exploring how Additive Manufacturing could support your marine, subsea, defence, or oil & gas operations, get in touch with our team – we’ll help you design and produce watertight solutions tailored to your needs.