Faster Than Your Supply Chain: The Power of 3D Printing for the Factory Floor

One material, five applications.

Wednesday 18th June 2025

When it comes to manufacturing, finding smart, cost-effective ways to solve everyday problems on the factory floor can make a real difference. What if you could solve challenges using just one material, and do it faster and cheaper than your traditional supply chain allows?

That’s the power of Additive Manufacturing.

With

Markforged Onyx material, a high-performance Nylon blended with micro carbon fibres, engineers are printing strong, reliable parts that hold up to industrial use, straight from the printer.

To show what’s possible, we set ourselves a challenge: one material, multiple applications.

The results? A selection of practical tools and fixtures for the factory floor, like a drill guide, an inspection gauge cover, and a wiring loom bracket, each printed in Onyx on the

Markforged FX10.

This project is a hands-on look at how one material can power multiple solutions, unlocking time and cost savings without compromising performance.

Why Onyx?

We chose Markforged Onyx material because it strikes the ideal balance between strength, heat resistance (up to 145°C), dimensional stability and surface finish. It is also non-marring.

It’s a Nylon 6 blend material with micro carbon fibres, that can also be reinforced with continuous fibres of Carbon Fibre, Fibreglass or Kevlar, making it significantly stronger and stiffer than standard plastics, perfect for robust, industrial-grade parts.

Onyx parts come off the printer with a smooth, matte black professional finish that don’t require any further post-processing. What’s more, components such as threads, nuts, sensors and electronics can be embedded during the print process augmenting the part further.

Why use AM on the factory floor?

Small delays in manufacturing operations have big knock-on effects. Often, sourcing a simple part like a jig, cable bracket or assembly guide means waiting weeks or meeting high minimum order quantities from external suppliers, just to get one or two components. These long lead times and costs don’t align with the fast pace and tight margins of today’s manufacturing world.

Additive Manufacturing offers quick wins, producing useful, custom parts on demand, at low cost. It gives manufacturers more control, greater flexibility, and the agility to solve problems the moment they arise.

Real Applications, Real Impact

To bring this concept to life, we identified a handful of everyday factory tooling and fixtures that are typically needed in small quantities, yet often slow or expensive to source externally. Using just one material (Onyx) we printed each of them in-house on a Markforged 3D printer, proving just how quickly these parts can go from idea to implementation.

Here’s what we printed:

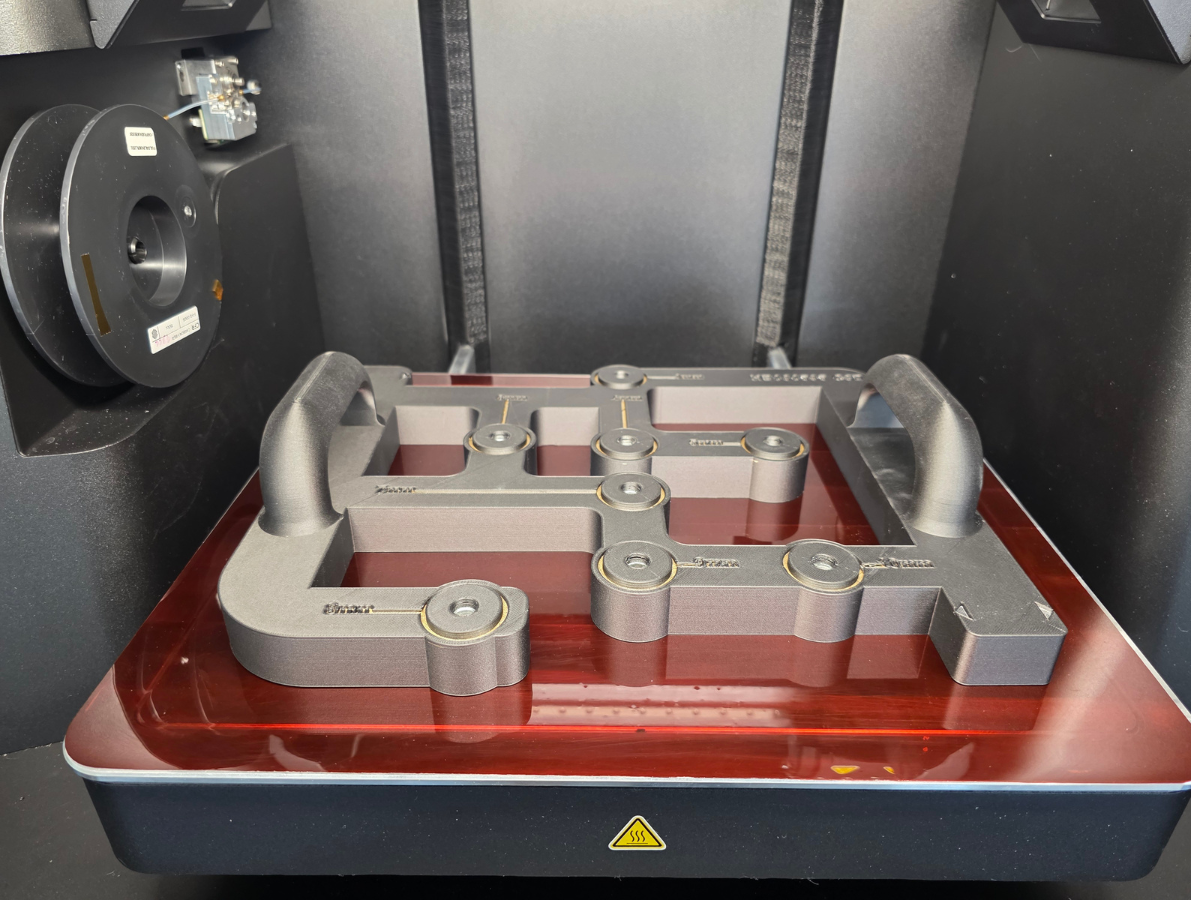

1. Assembly Tray

A custom-designed modular tray with a central fixture and multiple exact-fit compartments for organising specified components during assembly.

Used on assembly lines or workbenches to hold parts in a logical layout for efficient workflow and to reduce errors during assembly.

Print time: 22 hours

Part cost: £46.58

2. Drill Guide

A light-weight precision tool with multiple drill holes ranging from 3mm to 10mm, used to guide fixings accurately on complex surfaces.

Ensures accurate hole placement specific to the designed component.

Reduces risk of error, damage and high scrappage costs. Onyx is non-marring, so guide does not damage surface during use.

Print time: 1 day 12 hours

Part cost: £154.35

3. Inspection Gauge Cover

A durable cover designed to protect precision inspection tools when not in use, extending the life of the tools whilst withstanding tough factory environments.

Casing prevents damage from accidental drops or debris in workshop environments. It also enables existing tools to be mended, repaired and re-used, instead of being disposed of.

The gauge cover can be printed as a single part.

In many cases, the original casing breaks, making the tool unusable. Replacement covers often have high minimum order quantities, or worse, the only option is to buy an entirely new tool, which can be expensive.

Print time: 7 hours

Part cost: £11.03

4. Wiring Loom Bracket

A light-weight, custom fixture used to organise and route wires of various diameters to keep production or assembly environments tidy and efficient.

Onyx is also available as ESD-safe version, for when brackets are to be used in electronic environments.

Print time: 4 hours 17 minutes

Part cost: £7.88

5. Strap Wrench

A custom-designed wrench that applies or releases force safely. Uses a flexible strap to grip, loosen or tighten cylindrical or irregularly shaped components without causing surface damage.

Tool handle can be shaped or lengthened to fit in tight or awkward spaces, or be custom designed to fit specific operators.

Print time: 2 hours 56 minutes

Part cost: £6.08

AM is a Go-to Tool for Engineers

Each of these parts highlights a different strength of AM, whether it’s speed of turnaround, cost-saving or customisation. More importantly, they’re all examples of how engineers can take control of small but critical problems with the right material and the right technology.

This project of 1 material, 5 applications is a simple demonstration of what’s possible when you combine the right material with Additive Manufacturing know-how. Engineers don’t have to wait weeks or rely on external suppliers for functional, factory-ready parts. Whether it’s a one-off tool or a small batch of fixtures, you can design, print and use them, all in a matter of hours.

It’s fast, cost-effective and gives teams the flexibility they need to keep production moving.

Contact us to explore incorporating AM into your shop floor.