How 3D Printing is Transforming UK Food & Beverage Manufacturing

Tuesday 29th July 2025. Updated 23rd October 2025.

In the fast-paced world of food and beverage production, pressure is mounting: rising costs, long lead times, unreliable supply chains, and increasing pressure to do more with less. Additive Manufacturing (AM) provides a fresher approach to solving these longstanding challenges, offering a flexible, cost-effective way to boost operational efficiency and keep your production lines moving.

Whether you operate processing lines or build packaging or processing machinery, integrating Additive Manufacturing into your workflow unlocks serious benefits; from lowering operational costs, reducing reliance on worldwide suppliers, reducing warehousing and inventory, as well as increasing agility.

Streamline Operations with Custom Tooling

Traditional manufacturing often grapples with high costs, long lead times, high minimum order quantities and zero flexibility on design changes.

3D printing addresses this by enabling the rapid production of:

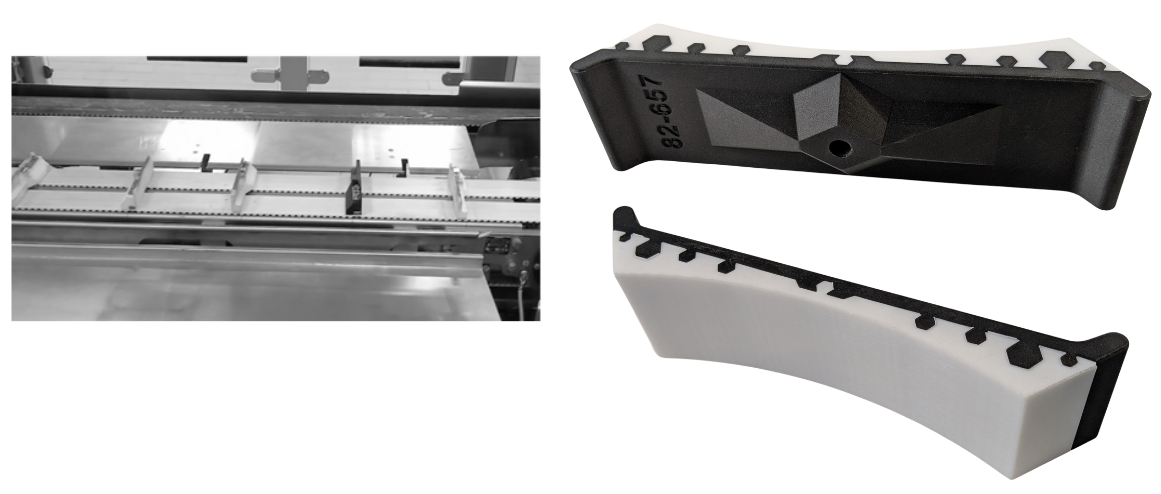

- Custom brackets and conveyor guides: Tailored components fit existing machinery for better performance and durability

- End-of-arm tooling (EOAT) and vacuum lifting tools: Lightweight, bespoke tools that enable easy changeovers and provide greater robotic agility

- Safety guards and ergonomic handles: Specifically designed for operator comfort, efficiency and safety

By printing these in-house, manufacturers significantly reduce downtime, avoid high MOQs and lower maintenance costs.

Reduce Inventory and Operational Costs

Additive Manufacturing enables on on-demand part production, at the point of need. This removes the need to stockpile spares, or wait weeks for deliveries

- Reduce warehouse space:

Digital files replace physical inventory, freeing up space and tied-up capital

- Make existing machinery more versatile:

Adaptable tooling enables a single machine to be more flexible, enable faster changeover, and minimising line down time

- Extend machinery lifespan:

Lightweighting parts through AM reduces machine wear and tear, leading to longer equipment life

- Repair instead of replace:

3D print replacement or broken components, at time of need, with no minimum order quantities

Explore Non-Food Contact as well as Food Safe Applications

Many manufacturers start with non-food contact areas, and there are plenty of quick wins.

With a range of engineering and specialist materials including non-marring Nylons, reinforcing continuous fibres, elastomers, silicones and metals including 17-4 and 316L Stainless Steel, there are multiple applications that can instantly benefit from switching to AM away from traditional manufacturing.

Further to this, advances have also led to food safe and metal detectable materials being readily available including:

Markforged Nylon White FS:

An NSF-certified, FDA-compliant material ideal for food-contact components such as guides and end-effectors

Metal Detectable Materials for Safer Production

For manufacturers operating in regulated areas such as food processing and packaging, foreign object control is essential. That’s where metal-detectable 3D printing materials come in.

Operating with the Formlabs Fuse 1+30 W SLS system, a PA11 DETECT specialist material has been designed for safety-critical environments, combining metal and optical detection within a single, food-safe compliant material.

Made from bio-based PA11, the material meets the highest food safety standards, including EU 1935/2004, EU 10/2011, and FDA CFR 21 compliance.

It features a blue optical safety indicator and a composite polymer with magnetite for metal detection, helping ensure any fragments can be identified during production.

Industrial 3D printer solutions include the Markforged FX10 and Formlabs Fuse SLS system, delivering accurate, durable parts that are printed in hours and at low cost.

Agility for the Pet Food Sector

In today’s fast-paced pet food industry, agility is everything. Customer preferences are changing rapidly, with increasing demand for breed-specific, age-tailored and premium nutritional options. Product variety is growing, and production lines need to keep up.

3D printing helps manufacturers stay ahead. From quick-turn change parts to size-specific pushers or new end-of-line tooling, Additive Manufacturing allows teams to adapt lines quickly, trial new products with less risk, and reduce the time and cost of launching new SKUs.

For pet food manufacturers and brands, that means faster responses to market shifts, without compromising productivity.

Real-World Results

Custom Safety Guards on Demand

A packaging team identified a pinch hazard on a bundler spindle, but no off-the-shelf guard existed. Instead of halting production or waiting days for a fix, they used Markforged printers to produce a custom-fit safety guard in hours, using existing mounting points.

This approach enabled:

- Rapid hazard resolution without waiting on external suppliers

- Custom geometry tailored to the specific line layout

- Ongoing digital storage of guard designs for future deployment

By empowering site teams to solve problems on-site with 3D printing, safety and uptime both improved.

Read storyDanone's Success Story

Danone's Dairy Plant in Poland exemplifies the tangible benefits of integrating Markforged 3D printers.

Not only did they realise 80% reduced part costs, they were also able to improve efficiency and speed of changeover with bespoke tooling and enhanced operator safety with custom safety guards.

Read storyFaster Bottle Development

Unilever and partner Serioplast used Formlabs SLA 3D printers to create moulds for stretch blow moulding (SBM), cutting pilot testing lead times from 6–8 weeks to just 2 weeks, and slashing costs by up to 90%.

The 3D printed moulds enabled:

- Realistic bottle prototypes made from production materials

- Consumer testing before committing to expensive tooling

- Earlier validation of production lines and packaging equipment

This accelerated packaging innovation while reducing sunk tooling costs and time-to-market.

Read full story

Start your AM Journey

Additive Manufacturing isn’t just for prototyping anymore, it’s a production-ready tool that’s already delivering real ROI for F&B manufacturers. Explore more applications on our

F&B Industry page.

From bespoke tooling to food-safe parts, our team at CREAT3D can help you get started. Talk to us today and discover what’s possible on your line.